Resources

Waste management: prevention takes priority

Various types of waste and recyclable materials are generated at Munich Airport, for example in the passenger area, in office buildings, and also during construction work. Flughafen München GmbH is authorized to conduct waste management independently on its site in accordance with the German Waste Management and Product Recycling Act. Avoidance of waste is an absolute priority. We also ensure that waste and recyclable materials are collected in various separation systems, transferred to certified waste management companies near the airport, processed in sorting facilities, and then recycled or reused. The small proportion of residual waste that cannot be recycled is converted by the Munich North power plant into district heat and power.

The continued rise in passenger numbers generated significantly more waste and recyclables in 2023. Numerous new construction and renovation measures across the entire airport campus led to an increase in construction waste. To live up to our responsibility for sustainable waste management and to make existing processes as resource-efficient as possible, we maintain a constant dialogue with customers and employees. Individual disposal concepts take into account the different requirements and conditions of waste producers. In particular, the highest possible degree of purity makes recycling processes easier.

The waste management industry is constantly evolving due to external influences such as digitalization and the climate debate. Starting in 2024, for example, Europäische Wirtschaftsdienst GmbH will cease providing the price index and reporting on the waste paper market for the «old newspapers» waste fraction. This is due to the sharp decline in the volume of waste paper and the decreasing importance of paper production. For this reason, we will remove all newspaper presses set up on campus. At the same time, all waste that is sent for thermal recycling is subject to a CO₂ tax. The aim is to incentivize people to avoid or recycle waste in order to ultimately reduce CO₂ emissions. In future, we will therefore be even more meticulous about separating waste.

Water management: conserving natural resources

The aim of water management at Munich Airport is to affect the natural water balance as little as possible and to minimize any adverse effects caused by water management, drainage, and drinking and firefighting water supplies.

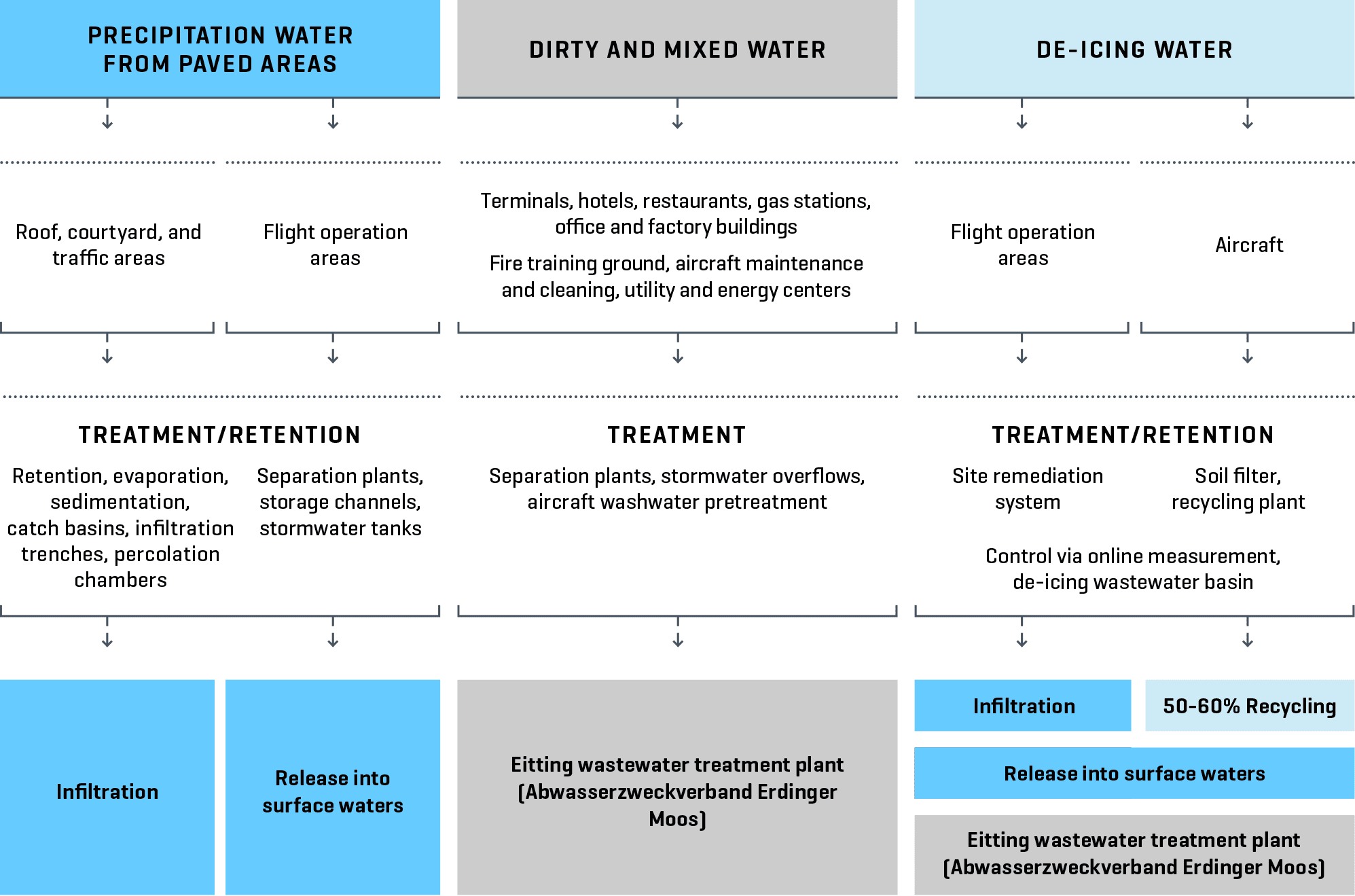

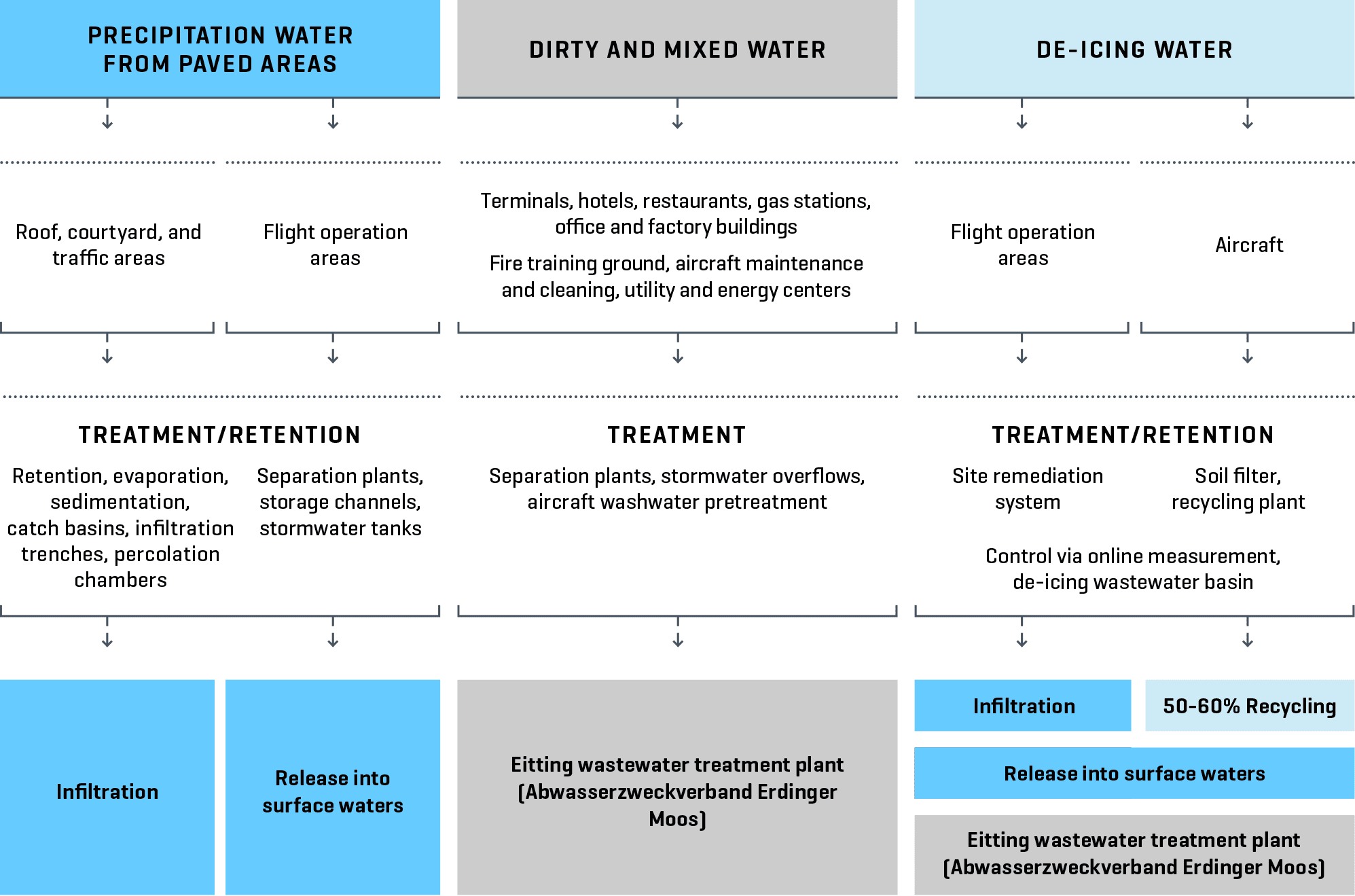

Wastewater disposal concept

Process water reduces drinking water consumption

By 2019, annual drinking water consumption at Munich Airport hovered consistently at around one million cubic meters, despite growth in passenger numbers. Due to the pandemic, the amount of drinking water purchased from the Zweckverband zur Wasserversorgung Moosrain decreased to less than 600,000 cubic meters in 2020 and 2021. In 2023, water consumption increased again to 891,705 cubic meters.

Where drinking water quality is not required, Munich Airport is increasingly using process water: for concrete work and construction site moistening, for cleaning runways, for wet sweepers, for cleaning sewers, and for watering green areas, shrubs and trees. Another process water well was put into operation for these purposes in 2022. For the cooling of the West Power Station, near-surface quaternary groundwater (process water) from a specially drilled well is used instead of tertiary groundwater (drinking water). Since process water pumping began in 2010, the total savings add up to 2,854,250 cubic meters.

Process water instead of drinking water for air conditioning purposes

Aircraft de-icing: recycling rate at a high level

De-icing vehicles keep aircraft free from ice and snow before take-off. The de-icer dripping off the aircraft during this process finds its way via slit drainage gutters and channels into underground basins. At the recycling plant at Munich Airport, it is treated mechanically and chemically to recover type 1 de-icing agents. The recycling rate for the active ingredient glycol contained in the product was 58.9% in the 2022/2023 winter season. To date, it has ranged between 41 and 60 percent and depends heavily on the weather, the amount of de-icing agent used, precipitation, and evaporation.